CHALLENGE BOUNDARIES

TEXTILE & GARMENT ENZYMES

One of oldest industrial use of enzyme was in the Textile Industry. It started with the usage of Amylase for starch removal in De-sizing.

Today speciality enzymes have been developed for usage by textile industry in Biological scouring, anti-pilling, fabric polishing, garment washing, fading and stone washing.

Enzymes are used for removal of residual Peroxide and Dye bath Bio-polishing is gaining popularity with increasing environmental and cost concerns.

Enzyme strains isolated from diverse biological environment are further engineered to Stone wash Denims at cold water, resulting in low back-staining and superior finish. Epygen Enzyme Scientists have tried to understand the complex nature of a natural substrate as in cotton and improve efficiency of enzyme usage by customizing the enzyme protein.

Epygen Enzymes are well accepted in the dynamic Textile and Garment Processing Industry for the innovative nature of its range which taps high levels of science with an eye for fashion trends, making processes cleaner, better and more affordable.

PRODUCTS

- ACID BIOPOLISH ENZYME

- NEUTRAL BIO-POLISH / DYE-BATH ENZYME

- BIO-SCOURING / BIOPOLISHING

- ENZYMATIC BLEACH CLEAN-UP WITH DE-PILLING

- DE SIZING ENZYME

- GARMENT FINISHING

A suitable combination of Endo Glucanase and Cellobiohydrolase tenders micro-fibrils protruding from the surface of yarn in the wet process, and the weakened micro-fibrils break off from the main body of the fibre leaving a smoother yarn surface, preventing pilling. Bio-finishing also results in a softer, smoother and optically enhanced fabric.

Name

Retrocell® PLX

Description

Engineered Cellulase with critical balance between endo and exo activity for aggressive fuzz removal in knitted and woven fabric at low dosages.

Apart from Bio-polishing on the fabrics, this enzyme treatment offers a number of other benefits in physical properties such as improvement in pill resistance, cooler feel, luminosity of colors and softness etc.

PLX is engineered to offer below benefits on fabric:

- Aggressive de-pilling

- Efficient fuzz removal

- Superior Hand-feel

- Strong Color pull/ abrasion on Garments

Name

Retrocell® BPL

Description

Is an aggressive Concentrated liquid Bio-polishing Cellulase, produced by Fermentation of a non-pathogenic fungi, genetically developed for hydrolysis of cotton Micro-fibril in knitted or woven fabric, at LOW DOSAGES.

At low dosages, Retrocell BPL removes surface fuzz under milder conditions and is absolutely safe, efficient and permanent. This enzyme gives fabrics a clear, even surface appearance. This treatment reduces tendency to pill and improve intrinsic softness of fabric, when compared to traditional softeners.

Once applied on fabric surface, it offers:

- Efficient Bio-polishing at Low Dosages

- Superior hand feel

- High Yield

- Controlled strength loss

Name

Retrocell® PL 6X Plus

Description

Super concentrated Acid Bio-polishing Cellulase enzyme for 4-5 times Dilution by formulators. This enzyme is produced by non-pathogenic fungi, specially optimized for high protein expression levels and efficiently depolymerize selected components of cotton fabric, resulting in fuzz and pill ball removal in Jet Dyer or Soft Flow equipment.

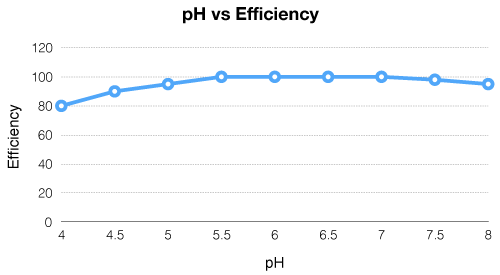

PL 6X is concentrated form for Acid Biopolishing enzyme, meant for dilution only. Diluted product may run between 4.5 to 5 pH and 55 to 60 Degree C temperature for 30 to 45 minutes to achieve following results:

- Aggressive fuzz removal

- Efficient Bio-finishing of fabric

- Highly effective for white Dyeing

Name

Retrocell® PL Eco G

Description

This is a robust Neutral Cellulase enzyme for efficient fuzz removal and softening of fabric surface, under neutral condition. This is produced by submerged fermentation process from harmless microbial species.

Retrocell PL Eco G works efficiently at much wider pH ranges than conventional Acid Cellulase, removing the need for regular pH check after fabric dyeing or bleaching. Simplifying the Dyeing and polishing process into same bath, eliminating checks and drains, this special feature helps in drastically reducing fabric processing time and energy. This in turn results in consistency of end product after each batch and sigficant cost saving for processor.

PL Eco G demonstrates benefits as below:

- Robust Neutral Bio-polishing, needs least process control!

- Simplify Dyeing and Polishing by combining

- Better color retention

- Less Acid consumption

- Less strength loss over conventional Acid Cellulase treatment

CASE HISTORY

Mill Parameter

Capacity: 35 tons dyeing capacity/ day

Machine: Schlavos/ Fongs/ Thies

Fabric: Jersy/ Pique/ Lacoste/ Rib/ Interlock/ Fleece

Application: Once scouring-bleaching is done, PL Eco is dosed at 0.3% fabric wt/wt, run for 10 minutes in same bath. Then ran salt ( 10 mints)/ dyes ( 20 mints)/ labelling (10 mints) on subsequent addition. Once treatment is carried out for 40 minutes, water drained.

Swatch was cut to see the enzyme performances and followed by alkali treatment before softening and finishing of fabric.

Benefits:

- Clean fabric surface with less pill tendency

- 2 hours of time saving / batch

- 7 kg of water saving/ kg fabric processed

- 25 % saving in Utility bill (Electricity/ steam/ energy bill)

- 10% saving in labour

- Better color retention

Name

Retrocell® PL Eco Plus

Description

Concentrated Neutral Bio-polish enzyme for bio-polishing and bio-softening of fabrics, at Low dosages (0.2 to 0.3%). This enzyme is highly accepted among mill engineers mainly due to dose economy.

Retrocell® PL Eco Plus is a concentrated Neutral Bio polish enzyme for fuzz removal on fabric for a clean and even surface appearance, at a wide range of pH (Neutral). This enzyme can be used in the Dye Bath, without the need of pH control and bath drop/change. Unlike softener, PL Eco Plus accomplish the jobs without polluting the environment and conserving precious resources like water, time and chemicals.

PL Eco Plus offers below advantages:

- Efficient fibril and pill balls removal at Low Dosages

- Simplify Dyeing and Polishing by combining

- Better color retention

- Less Acid consumption

- Less strength loss over conventional Acid Cellulase treatment

Usual chemical scouring followed by Mills, utilises harsh chemicals like Caustic to remove wax, pectin etc. from fabric. Harsh alkalys and oxidizers are known to be harmful for fabric, environment and individuals. Subsequent to Scouring, fabric is subjected to Biopolishing prior to Dyeing.

Epygen Scientists have developed a single step Bioscouring and Biopolishing enzyme Retrocell BSL, drastically simplifying the process.

Name

RetroCELL® BSL

Description

Pectolytic enzyme with Cellulase activity, co expressed by non pathogenic microorganism in controlled fermentation process. BSL simplifies and combines Scouring and Polishing steps as it removes pectin efficiently while simultaneously de-pilling fabric surface.

This is a unique combination of Bio Scouring (Pectate Lyase) enzyme with enhanced Cellulase activity designed to remove pectin from grey fabric and microfibril from fabric surface in a synergistic manner.

BSL offers following benefits when used suitably:

- Efficient removal or Pectin/ Wax with other impurities from cotton

- Increase Yarn smoothness, pliability and absorbance

- Efficient De-pilling and pill ball removal

- Significant reduction of BOD/COD

- Saves Water/ Energy/Time and Chemicals

Epygen’s Retrox series of Catalases are Oxido Reductase enzyme, efficiently decompose residual peroxide after bleaching, which otherwise may cause a patchy dyeing problems in mill. Epygen combines the biological processes of bleach clean-up and bio-polishing for an efficient process.

Being a combined biological process, this does not require excessive washing between the bleaching and dyeing stages.

Name

Retrcell® SynerG

Description

One step Catalase enzyme with Polishing Cellulase activity, suitable for decomposition of high concentrations of Hydrogen Peroxide into Oxygen and Water at low dosages. Since this enzyme is totally inert to Reactive Dyes stuffs, it is preferred for Peroxide killing, post bleaching, prior to dyeing, as it also performs Bio-polishing simultaneously.

SynerG is a unique combination of Biological Catalase & Cellulase activity, allowing mill processors to carryout fuzz removal operation along with bleach clean up and Dyeing, all in one shot. This allows substantial saving in processing resources like time, water, energy and chemicals. The simplication of process reduces manpower cost and human error, delivering an overall improvement to mill efficiency.

Below are few advantages from SynerG:

- Increased production throughput

- Saving in time and fabric wet processing cost

- Even Dyeing

- Controlled strength loss of Fabric

- Reduced Human involvement and human error

- Improved effluent quality

Name

Retrostar DA

Description:

Retrostar DA is a biodegradable, broad-spectrum Amylase enzyme for Textile De sizing. It breaks down starch into normal sugar.

Retrostar DA is a specially developed amylase for multipurpose de sizing with flexibility for Fabric/ Garments sized with starch, starch derivatives or starch polymer blends.

Few important features of Retrostar DA are:

- Efficient Enzymatic De sizing.

- Highly effective for exhaust, pad steam & cold/hot pad batch.

- Compatible with Textile wetting agents, detergents, scouring agents.

Name

Retrocell® NeoP

Description

Hot Neutral Cellulase enzyme (powder) with controlled Back-staining. This enzyme system has been developed by specialized fungal technology.

Retrocell NeoP is a formulated Neutral Cellulase consisting of pH stabilizing buffer, anti -redeposition agent and an efficient dispersing component, all in one product. NeoP is a true Neutral powder enzyme for stone wash effects on Denim Garments with a new improved wash look, in an eco-friendly way.

NeoP creates below wash effects, on Denim:

- High abrasion with lowest back staining

- Distinct white grains on Denim Garments

- Pepper-Salt effects

- High contrast with a superior finish

- Controlled fraying and weight loss

True Neutral enzyme wash (With NeoP)

Other market Neutral enzyme wash (Semi-Neutral)

Name

Retrocell® RecoPJ

Description

Cold water powder Cellulase enzyme developed by recombinant technology.

An engineered Cellulase combined with excellent dispersing agent, this enzyme has been designed to wash Denim/ Non-Denim at low temperature, resulting in abysmally low back staining and good contrast. Due to special type of engineered Cellulase, this product maintains dark indigo True Tone of Denim, with a greyish cast.

Few special characteristics of RecoPJ are as below:

- Low back staining and high contrast

- Works at really low temperature, even below 20 Deg C

- Grey Cast with white pockets

- Effective puckering

- Superior finishing

Name

Retrocell® PL Eco G

Description

Cold water Liquid Cellulase enzyme developed by recombinant technology.

An engineered Cellulase combined with excellent dispersing agent, this enzyme has been designed to wash Denim/ Non-Denim at low temperature, resulting in low back staining and good contrast. Due to special type of engineered Cellulase, this product maintains dark indigo True Tone of Denim, with a greyish cast.

Few special characteristics of PL Eco G are as below:

- Low back staining and high contrast

- Works at really low temperature, even below 20 Deg C

- Grey Cast with white pockets

- Effective puckering

- Superior finishing